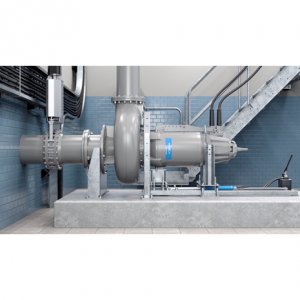

OPERATION OF DRY INSTALLED SUBMERSIBLE PUMPS

Flygt dry installed submersible pumps offers operational advantages in dry well pump stations:

• Leakage free operation. There is no external shaft seal that can leak wastewater into the pump room.

• Flood-proof motor. If the pump room is flooded, the submersible pump keeps on working.

• Motors bigger than 10kW feature built-in cooling that minimizes the power consumption of ventilation fans. Cooling is independent of the ambient air temperature.

Service is simplified without the need to dismantle the entire pump:

• The patented telescopic service hatch, or the patented pivoting inlet for sizes above 350 mm (14”) provides quick access to the pump suction side.

• Lifting equipment designed for handling of the motor and impeller

• Service cart and rails or sled with double acting hydraulic actuator gives easy access to the drive unit and impeller and ensures safe handling and an improved working environment for larger pumps (see table)

INSTALLATION COMPONENTS

The Flygt horizontal installation equipment is delivered with a sturdy stand including patented telescopic or pivoting service opening depending on pump model (see table).

Options include:

• Service lifting device

• Service cart or sled and rails depending on pump model (see table)

Features | Concertor | Low capacity N3000 pumps | Medium capacity N3000 pumps | High capacityC3000 & N3000 pumps | |

| 6020 | 3085 – 3127 | 3153-3315 | 3231-3312, 3356 | 3351,3400, 3501-3800 | |

| Service cart | • | • | • | ||

| Service sled, Hydraulic operated | • | • | |||

| Service inlet, Telescopic | • | • | • | • | |

| Service inlet, Pivoting | • | ||||