OVERVIEW

PROVEN PERFORMANCE WITH OVER 130 YEARS OF EXPERIENCE: HIGH EFFICIENCIES, LOW ENERGY COSTS AND WIDE OPERATING RANGE

- A wide range of available hydraulics enables the customization of pump selections to maximize pumping efficiencies. Pump efficiencies up to 91% save money on operating costs.

- Pumps are available in a wide variety of metallurgies to suit the particular application.

- Can be manufactured to NSF 61 compliance for drinking water.

- Horizontal or vertical mounting saves space and reduces station footprint.

- Choice of side suction or bottom suction allows application flexibility and lowers the construction costs.

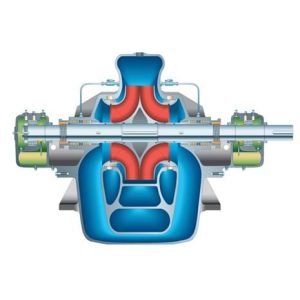

- Easy to install and service – flanges on common centerlines simplify piping layouts; axially split casing allows for ease of maintenance.

- Renewable impeller and casing wear rings permit easy maintenance of proper running clearances that will result in increased impeller service life and sustained operational efficiency.

- Heavy-duty design double suction impellers and dual volute casings (most sizes) minimize bearing loads and shaft deflections, therefore providing long term trouble-free operation.

- With full-scale performance testing capabilities up to 520,000 GPM (120,000 m3/hr) or 9850 HP (7350 kW) the performance of each pump can be accurately certified before it leaves the factory.

- Readily-accessible service centers, technical know-how, spare parts, and support to ensure minimal downtime costs and the most cost-effective operations.